Introduzione

As industries shift toward sustainable power solutions, rechargeable D batteries have become the preferred choice for companies that want to reduce long-term costs without compromising performance.

This guide explores everything you need to know about rechargeable D batteries—their chemistry, performance, applications, and most importantly, how to choose the right supplier for large-scale projects.

What Are Rechargeable D Batteries?

Rechargeable D batteries are cylindrical power cells with a standard dimension of 33 mm in diameter and 61.5 mm in length. Unlike disposable alkaline D cells, these rechargeable versions are built to be used hundreds of times. They are typically manufactured using nickel-metal hydride (NiMH), Nickel-Cadmium (NiCd) or lithium-ion (Li-ion) chemistries, each offering distinct benefits.

For industries, the difference is more than just environmental. Rechargeable D batteries lower total ownership cost, simplify logistics by reducing frequent replacements, and ensure that devices can operate reliably in demanding conditions.

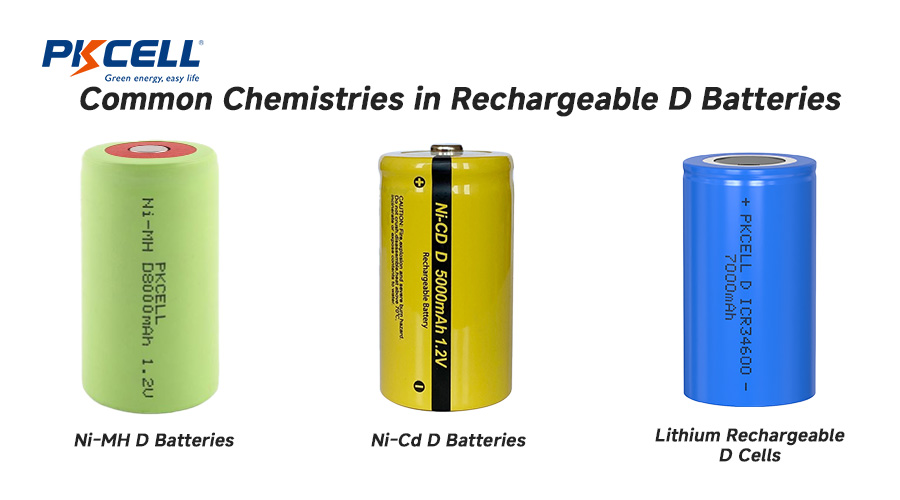

Common Chemistries in Rechargeable D Batteries

Nickel-Metal Hydride (NiMH) D Batteries

NiMH D batteries are today’s most widely used rechargeable option in the D-size format. They typically deliver a nominal voltage of 1.2V with capacities ranging from 2,000mAh to over 10,000mAh. Their high energy storage and stable output make them a practical choice for both consumer electronics and industrial equipment. They also have a cycle life of around 500–1,000 charge/discharge cycles, striking a balance between performance, cost, and sustainability. Because they are compatible with most existing D-battery devices and standard chargers, NiMH batteries have become the default choice for applications where reliability and ease of use are key.

Quote for PKCell NiMH D Batteries

Nickel-Cadmium (NiCd) D Batteries

NiCd D batteries, while less common today, are still found in demanding environments where durability is critical. These cells also operate at a nominal 1.2V, but typically offer capacities in the range of 2,000–5,000mAh. Their main strength lies in their ability to deliver very high discharge rates. This makes them dependable for emergency lighting, power tools, and backup systems. They can withstand over 1,000 charge cycles under proper maintenance, but the well-known memory effect can reduce capacity if not fully discharged before recharging. Despite the limitation, NiCd remains in use where robust performance and reliability under extreme conditions outweigh environmental concerns.

Lithium Rechargeable D Cells

Rechargeable lithium D cells are a newer option. These batteries generally provide a nominal voltage of 3.6V–3.7V, with capacities ranging from 3,000mAh up to 15,000mAh. They can last 1,000–2,000 charge cycles, far outpacing most NiMH and NiCd counterparts. Their higher voltage means they are not a direct drop-in replacement for standard D batteries, and they often require compatible electronics or protection circuitry. On the other hand, lithium D cells offer lighter weight, longer runtimes, and excellent storage life. They are gradually being adopted in industrial instrumentation, medical devices, and energy storage applications where performance justifies the higher cost.

| Tipo di batteria | Voltage (Nominal) | Gamma di capacità | Ciclo di vita | Applicazioni tipiche |

|---|---|---|---|---|

| NiMH D Battery | 1.2V | 4000 – 10,000 mAh | 500 – 1000 cycles | Flashlights, toys, portable electronics, backup power |

| NiCd D Battery | 1.2V | 2000 – 6000 mAh | 1000+ cycles (with proper maintenance) | Emergency lighting, medical devices, industrial tools |

| Lithium D Battery | 3.6V / 3.7V | 3000 – 12,000 mAh | 1000 – 2000 cycles | High-drain equipment, energy storage, advanced electronics |

Key Applications of Rechargeable D Batteries

Rechargeable D batteries are built for industries that demand dependable and powerful energy. Some of the most common applications include:

- Emergency Lighting Systems – Provides long runtime for safety compliance in commercial and public spaces.

- Dispositivi medici – Powers portable hospital equipment where reliability is critical.

- Industrial Tools – Supports testing equipment, sensors, and power tools in harsh environments.

- Audio Equipment – Used in professional sound systems and broadcasting gear.

- OEM Manufacturing – Integrated into products requiring stable rechargeable power packs.

For large-scale deployment, the choice of battery chemistry and supplier directly affects operational efficiency.

Performance Comparison: Rechargeable D vs. Disposable D Batteries

| Caratteristica | Rechargeable D (NiMH / Li-ion) | Disposable D (Alkaline) |

|---|---|---|

| Initial Cost | Più alto | Più basso |

| Long-Term Cost | Lower (reusable 500–1000 cycles) | Higher (frequent replacements) |

| Gamma di capacità | 2000–10000 mAh | 12000–18000 mAh (single-use) |

| Tensione | 1.2V (NiMH) / 3.6V (Li-ion) | 1.5V |

| Autoscarica | Low to Moderate | Very Low |

| Eco-Friendliness | High (reusable, less waste) | Low (single-use, landfill impact) |

| Industrial Preference | OEMs, utilities, medical, safety | Limited to consumer use |

This comparison highlights why industries increasingly prefer rechargeable D cells despite their slightly higher upfront cost.

Maintenance and Best Practices

To maximize the life of rechargeable D batteries, industries should follow simple but effective maintenance steps:

- Avoid Overcharging – Use smart chargers with automatic cut-off.

- Temperature Control – Store in cool, dry environments to prevent premature aging.

- Periodic Cycling – Fully discharge and recharge batteries every few months to maintain health (NiMH especially).

- Batch Tracking – For OEM use, maintain lot records to ensure quality and performance consistency across production.

The Future of Rechargeable D Batteries in Industry

The role of D batteries continues to evolve. With IoT integration and smart power systems, industries are demanding longer cycle life, higher energy density, and safer chemistries. Hybrid solutions, such as battery + supercapacitor packs, are also being explored to handle sudden power surges in devices like smart meters and medical pumps.

PKCELL is actively developing next-generation rechargeable D solutions to meet these demands, ensuring that industrial customers can keep pace with technological advances.

Why Choose PKCELL as Your Rechargeable D Battery Supplier?

PKCELL is a trusted supplier of rechargeable D batteries. We deliver reliable power solutions for businesses worldwide. With over 20 years of manufacturing experience, we produce high-capacity NiMH D batteries designed for long cycle life, stable performance, and eco-friendly reusability.

We focus on B2B supply, offering consistent quality, competitive bulk pricing, and full certifications including ISO9001, CE, and RoHS. Choose PKCELL as your rechargeable D battery supplier for dependable performance and long-term value.

Conclusione

Rechargeable D batteries are more than just an energy source—they are the backbone of countless industrial and commercial systems. For businesses managing large-scale deployments, the right battery solution can improve efficiency, reduce costs, and support sustainability initiatives.

By choosing PKCELL, OEMs and utilities gain access to reliable, certified, and customizable rechargeable D batteries. Whether for emergency lighting, medical devices, or OEM equipment, PKCELL ensures consistent quality and dependable supply.

FAQs About Rechargeable D Batteries

Q1: How long do rechargeable D batteries last?

Depending on chemistry and usage, they typically last 500–1200 cycles, which translates to 2–5 years in industrial applications.

Q2: Can rechargeable D batteries replace alkaline D cells in all devices?

OnOn most devices, yes. However, users should verify voltage requirements—NiMH provides 1.2V vs. 1.5V for alkaline.

Q3: Which is better for industrial use: NiMH or Li-ion D batteries?

NiMH is safer and more stable for high-drain, rugged applications, while Li-ion offers higher energy density and longer runtime for OEM integrations.

Q4: Why should OEMs buy from PKCELL instead of local suppliers?

PKCELL offers global-scale production, customization, certifications, and proven track records with utilities and industrial clients worldwide.

Batteria al litio ricaricabile USB

Batteria al litio ricaricabile USB